YB-12 High Voltage Low Voltage Prefabricated Substation

Product Features

1. The box is transformed into a frame structure, and the base of the box is welded with high-quality channel steel, which has high mechanical strength. The shell is made of aluminum alloy plate, coated with a special paint layer, and has a thermal insulation layer. The shell materials include composite plates, stainless steel composite plates, aluminum zinc plated plates, stainless steel plates, and metal carved plates, which have good anti-corrosion capabilities. The box transformer is designed with a dedicated lifting mechanism to prevent deformation of the box due to lifting stress. The base of the box and all internal and external metal components have undergone special rust prevention treatment and are coated with a durable protective layer. Doors, windows, and ventilation openings are equipped with measures to prevent dust, small animals from entering, and prevent water leakage. A temperature controller is installed inside the box to prevent component condensation.

2. The inclination of the top cover of the box shall not be less than three degrees. The bottom of the box is equipped with rainproof measures and moisture-proof and rust proof measures to prevent moisture and corrosive gases from entering the cable trench.

3. All doors of the transformer box are hinged outward, with an opening angle greater than 900 degrees, and equipped with positioning devices. The door is sealed and equipped with handles, rain proof, anti blocking, and anti rust measures

4. The top cover of the transformer box is insulated, and the transformer room and low-voltage room have dedicated exhaust channels and automatic exhaust systems with temperature controllers. The transformer room adopts a natural ventilation automatic control forced cooling air cooling device, with an exhaust system that automatically controls with temperature changes, which can effectively circulate the temperature inside the transformer box, prevent the transformer environment temperature from being too high, and achieve stable operation requirements.

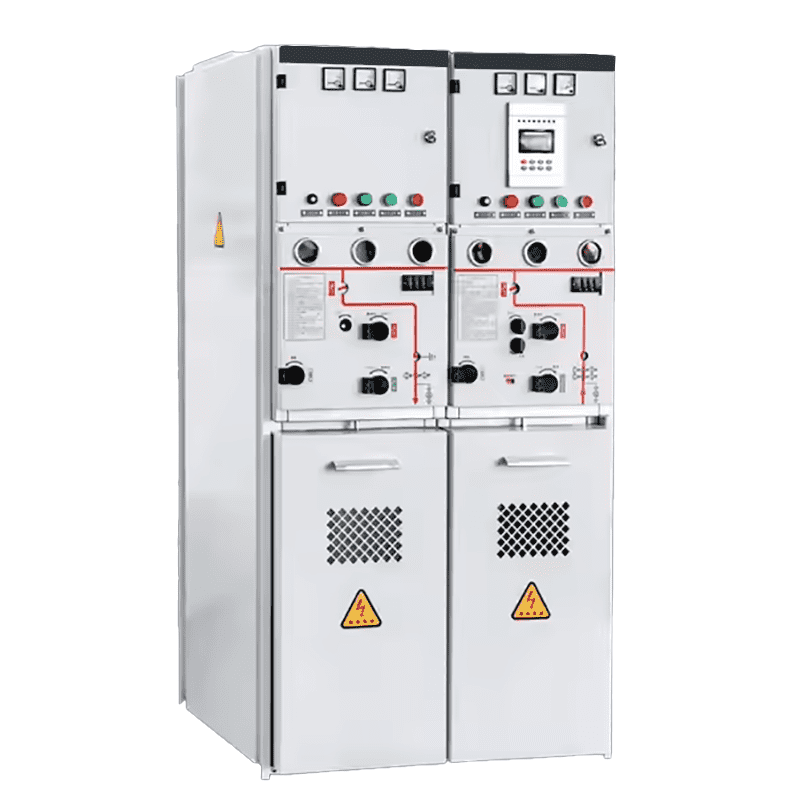

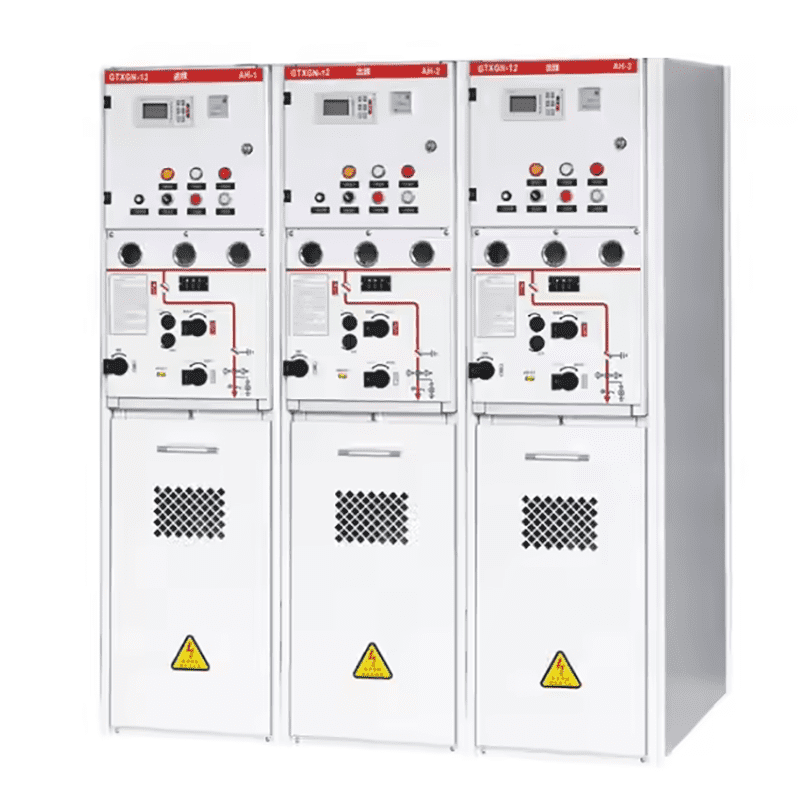

5. The substation is divided into independent high-voltage rooms, transformer rooms, and low-voltage rooms. The lighting in each room automatically turns on as the door is opened. The high-voltage room is equipped with high-voltage switchgear, which can be selected according to user needs and has five major preventive functions. The low-voltage computer room has the overall function of a complete set of low-voltage switchgear, and can adopt various structural distribution schemes according to user requirements, including power distribution, lighting distribution, reactive power automatic compensation, energy metering and other functions; Transformers can be dry-type or oil immersed.

6. The whole station is designed with intelligence, and the protection system adopts a substation microcomputer integrated automation device, which is installed in a decentralized manner and can achieve four remote sensing functions: telemetry, remote signaling, remote control, and remote adjustment. Each unit has independent operational functions and complete relay protection functions. Remote setting of operating parameters, control of humidity and temperature inside the box, to meet unmanned requirements.

Only logged in customers who have purchased this product may leave a review.

We are professional EV charger manufacturer.

This depends on the EV battery size, remaining battery capacity, and the type of EV charger used as well as environmental conditions such as temperature.Typically, an AC charger with an output power of 7–22 kW can fully charge an EV in between 3 and 6 hours.With a 50–200-kW DC fast charger, the charge time can be reduced to 10–60 minutes.

An AC charger provides AC power, which is then converted to DC power by an onboard charger inside the EV (before it reaches the battery). AC chargers are normally used in slow-charging applications such as home charging. A DC charger converts AC power from the grid into DC power, which is more efficient and supplies the batteries directly. Thus, the charging time is markedly shorter. DC chargers have higher power requirements and therefore a higher installation complexity. As such, the installation cost can be higher than that for an AC charger. DC systems are generally used in commercial/public charging applications where shorter dwell tines are needed

This depends on your situation. Fast DC chargers are ideal for cases where you need to recharge your EV quickly, such as at an intercity highway charging station or rest stop. An AC charger is suitable for places where you stay longer, such as workplace, shopping malls, cinema and at home.

.png) PV-Storage-Charging

PV-Storage-Charging-1.png) High & Low Voltage Switchgear

High & Low Voltage Switchgear Company Profile

Company Profile News Information

News Information Service Support

Service Support Cloud Platform Customized Development

Cloud Platform Customized Development Leisheng Charging International Platform

Leisheng Charging International Platform Leisn Home Charging Platform

Leisn Home Charging Platform

Reviews

There are no reviews yet.