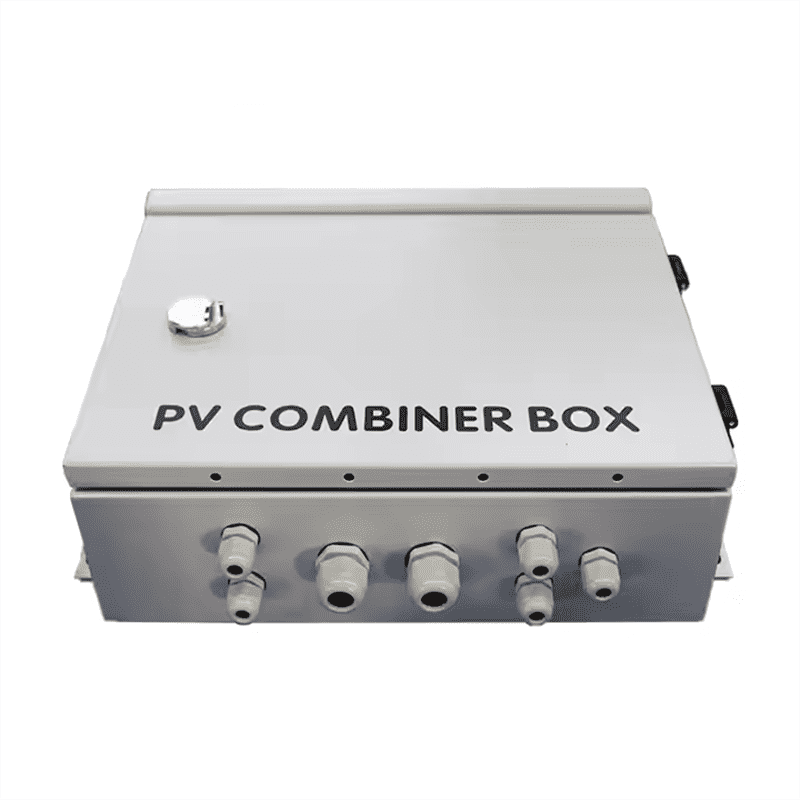

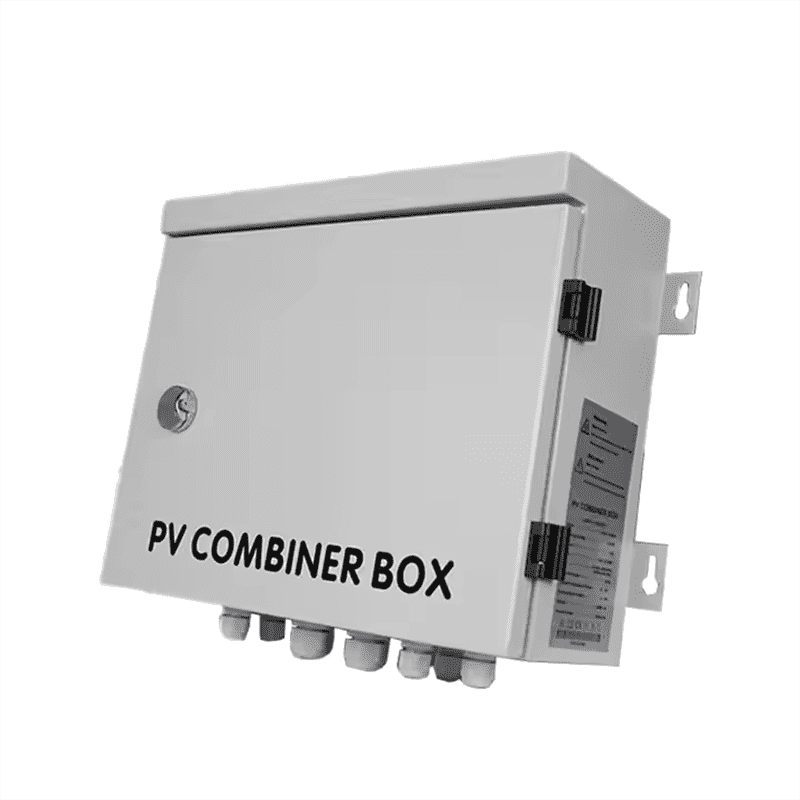

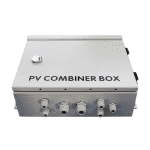

For large-scale photovoltaic grid connected power generation systems, in order to reduce the connection lines between photovoltaic modules and inverters, facilitate maintenance, and improve reliability, it is generally necessary to add a combiner device between the photovoltaic modules and inverters. Our company’s combiner box series products are specially designed to meet this requirement and are used in large-scale photovoltaic grid connected power generation systems. They are placed in front of the photovoltaic modules and inverters to reduce the length between them, facilitate system maintenance, and improve reliability. The photovoltaic array combiner cabinet can connect a certain number of photovoltaic modules with the same specifications in series to form one photovoltaic module string according to the DC voltage range input by the inverter, and then connect several strings to the photovoltaic Rixuan Rirui lightning protection combiner box. The output is after the Ningchoucun lightning protection device and circuit breaker, which facilitates the connection of the subsequent inverter.

Product Features

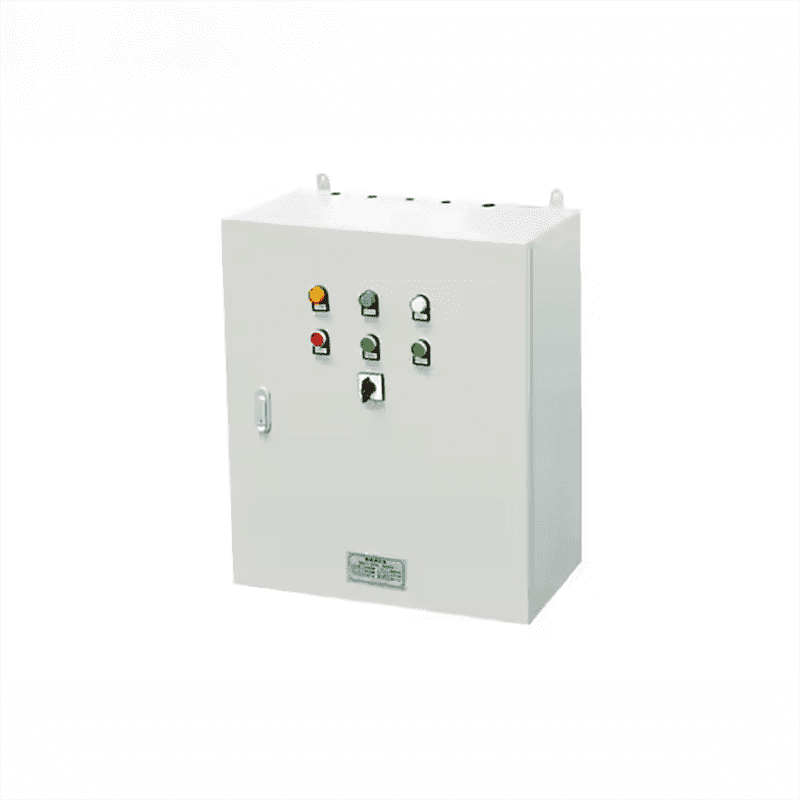

- The cabinet body is generally made of steel plate spray coating, stainless steel, engineering plastic, etc. It has a beautiful and generous appearance, is sturdy and durable, easy to install, and has a protection level of IP 54 or above.

- It is waterproof and dustproof, meeting the requirements for long-term outdoor use. At the same time, it can be connected to multiple photovoltaic arrays and equipped with insurance components (replaceable with other grades).

- Equipped with photovoltaic dedicated high-voltage lightning arrester, both positive and negative poles have lightning protection function.

- Adoptd with a four pole circuit breaker with positive and negative poles connected in series to improve the DC withstand voltage.

Only logged in customers who have purchased this product may leave a review.

We are professional EV charger manufacturer.

This depends on the EV battery size, remaining battery capacity, and the type of EV charger used as well as environmental conditions such as temperature.Typically, an AC charger with an output power of 7–22 kW can fully charge an EV in between 3 and 6 hours.With a 50–200-kW DC fast charger, the charge time can be reduced to 10–60 minutes.

An AC charger provides AC power, which is then converted to DC power by an onboard charger inside the EV (before it reaches the battery). AC chargers are normally used in slow-charging applications such as home charging. A DC charger converts AC power from the grid into DC power, which is more efficient and supplies the batteries directly. Thus, the charging time is markedly shorter. DC chargers have higher power requirements and therefore a higher installation complexity. As such, the installation cost can be higher than that for an AC charger. DC systems are generally used in commercial/public charging applications where shorter dwell tines are needed

This depends on your situation. Fast DC chargers are ideal for cases where you need to recharge your EV quickly, such as at an intercity highway charging station or rest stop. An AC charger is suitable for places where you stay longer, such as workplace, shopping malls, cinema and at home.

.png) PV-Storage-Charging

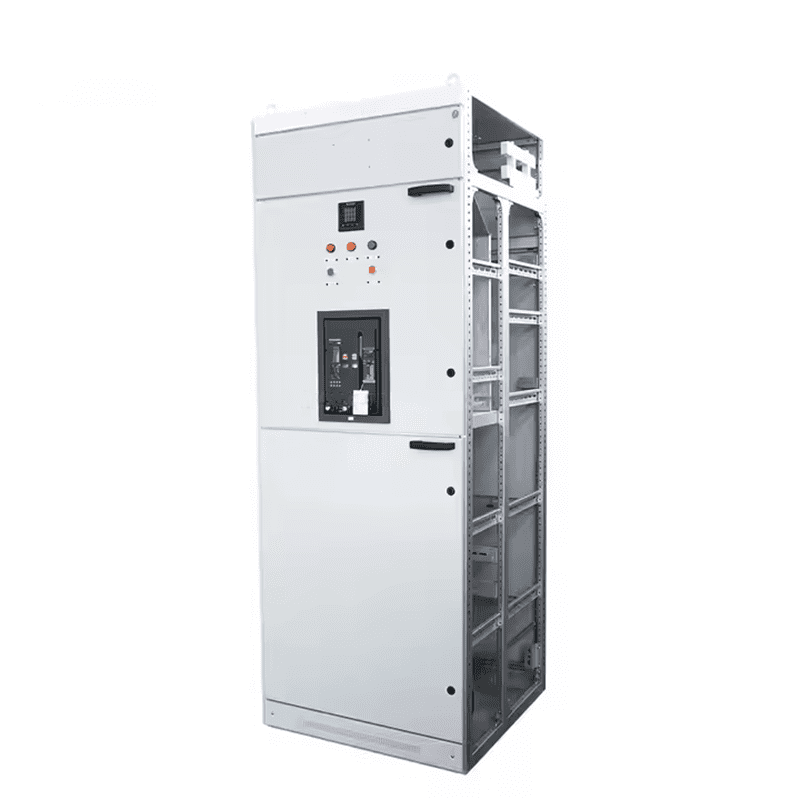

PV-Storage-Charging-1.png) High & Low Voltage Switchgear

High & Low Voltage Switchgear Company Profile

Company Profile News Information

News Information Service Support

Service Support Cloud Platform Customized Development

Cloud Platform Customized Development Leisheng Charging International Platform

Leisheng Charging International Platform Leisn Home Charging Platform

Leisn Home Charging Platform

Reviews

There are no reviews yet.