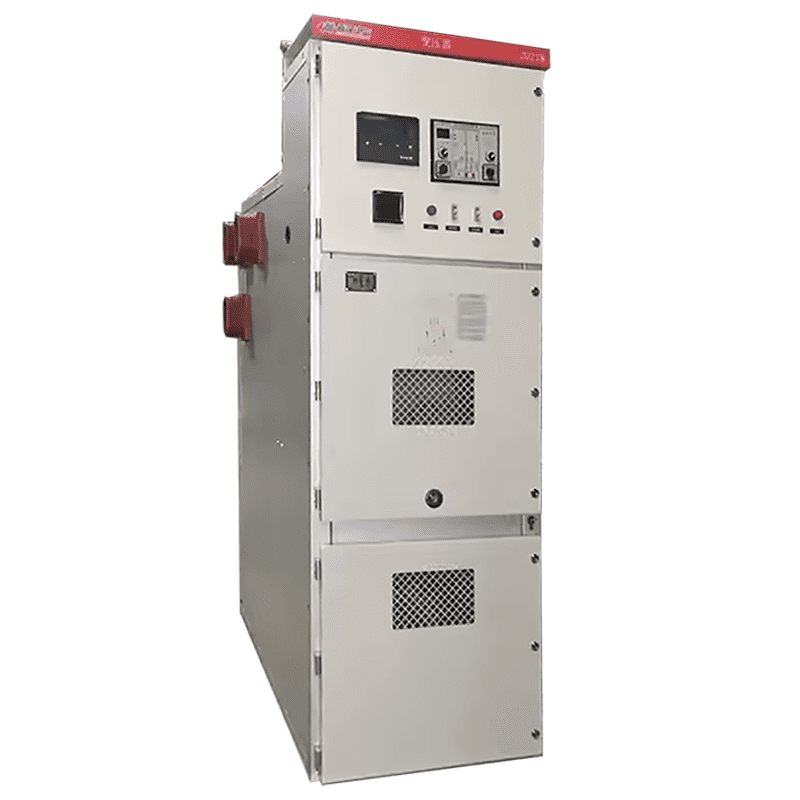

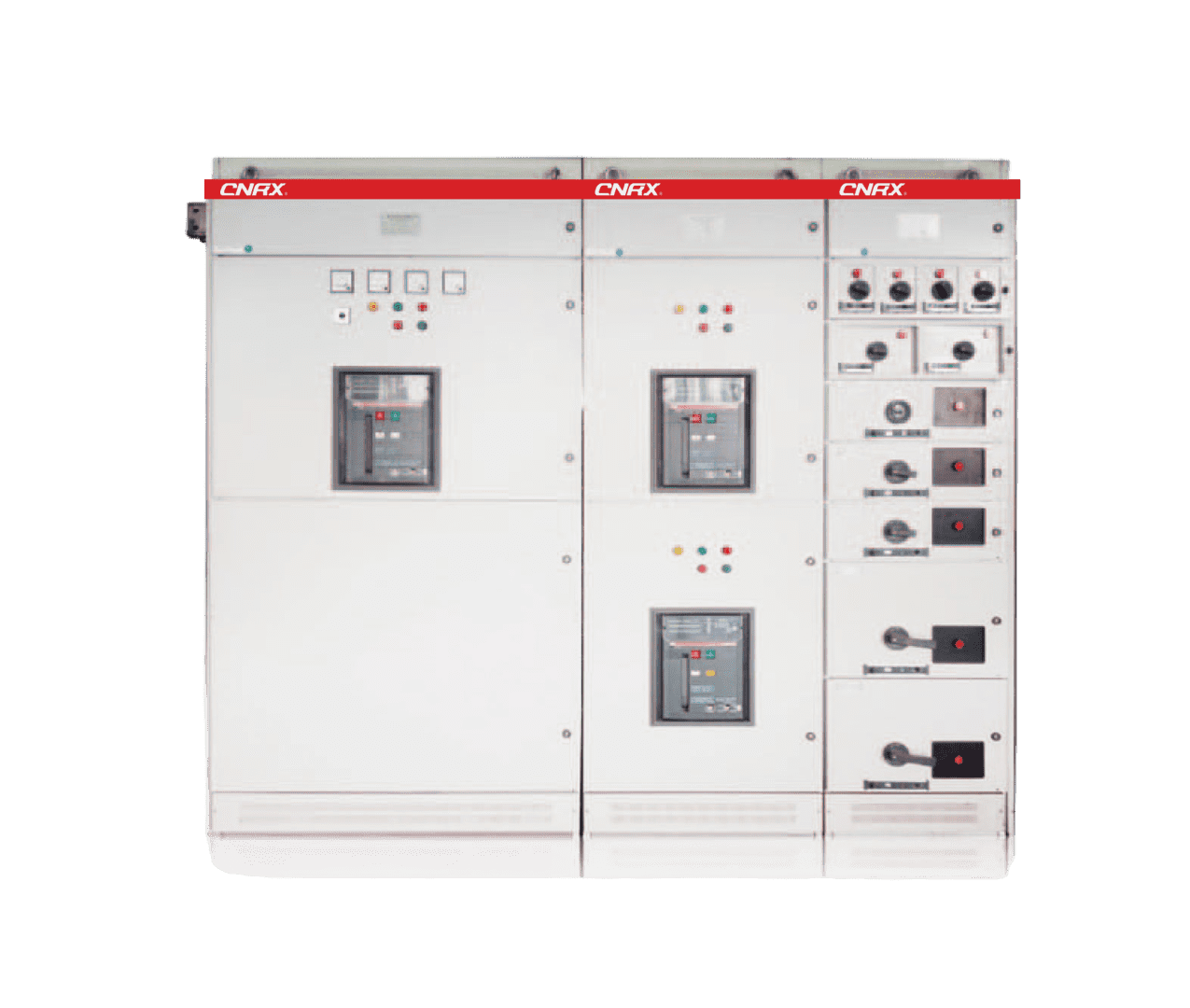

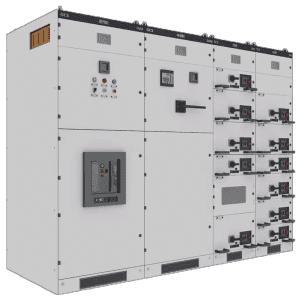

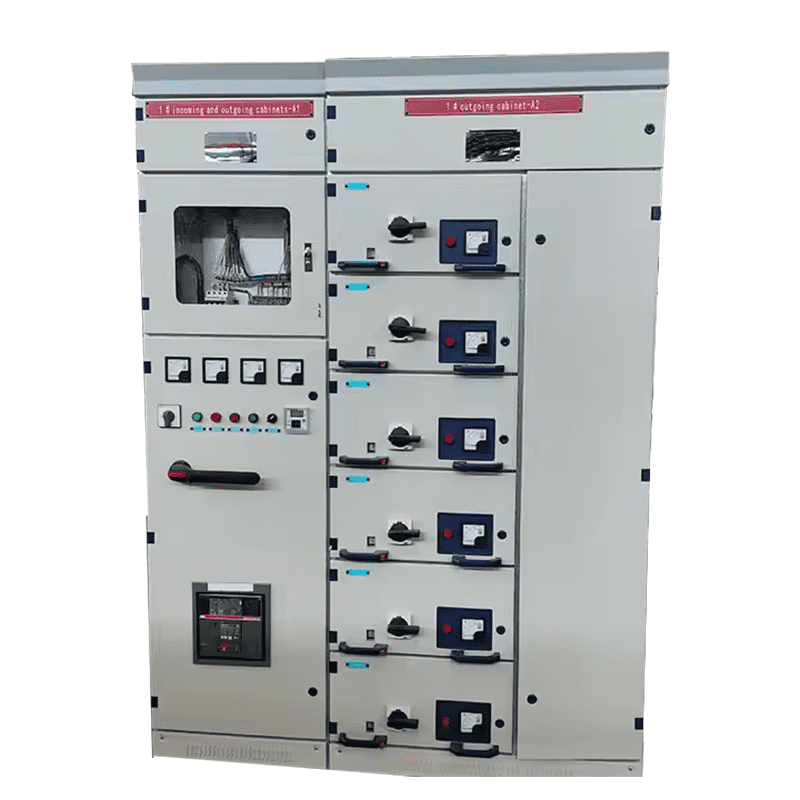

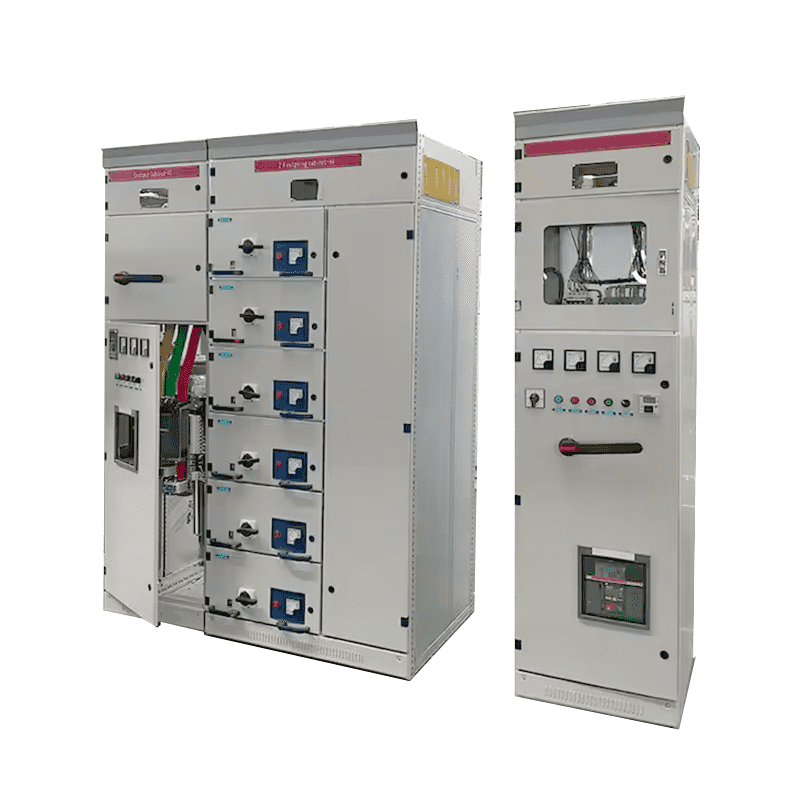

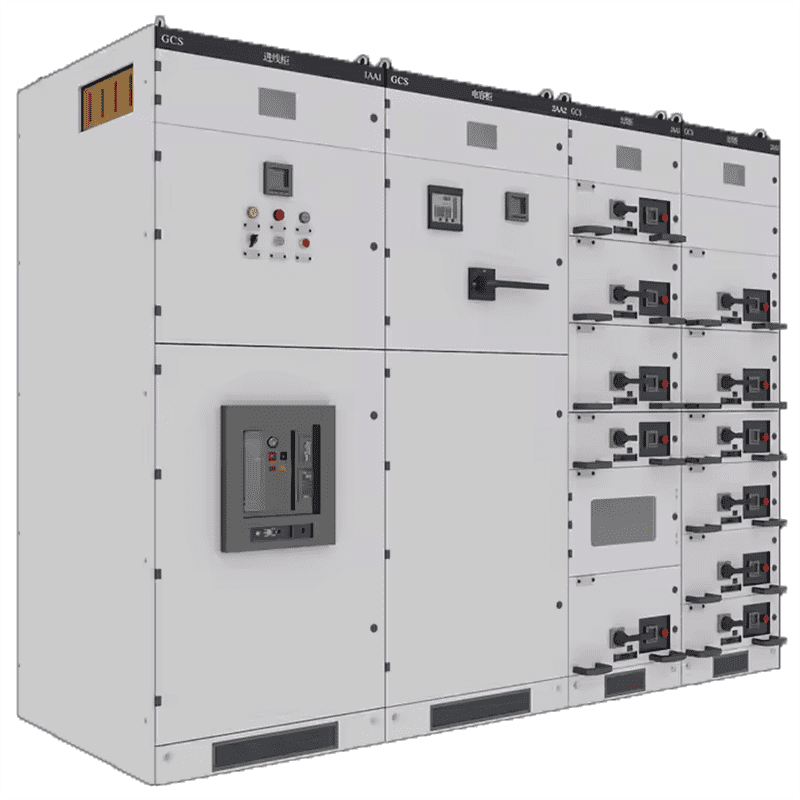

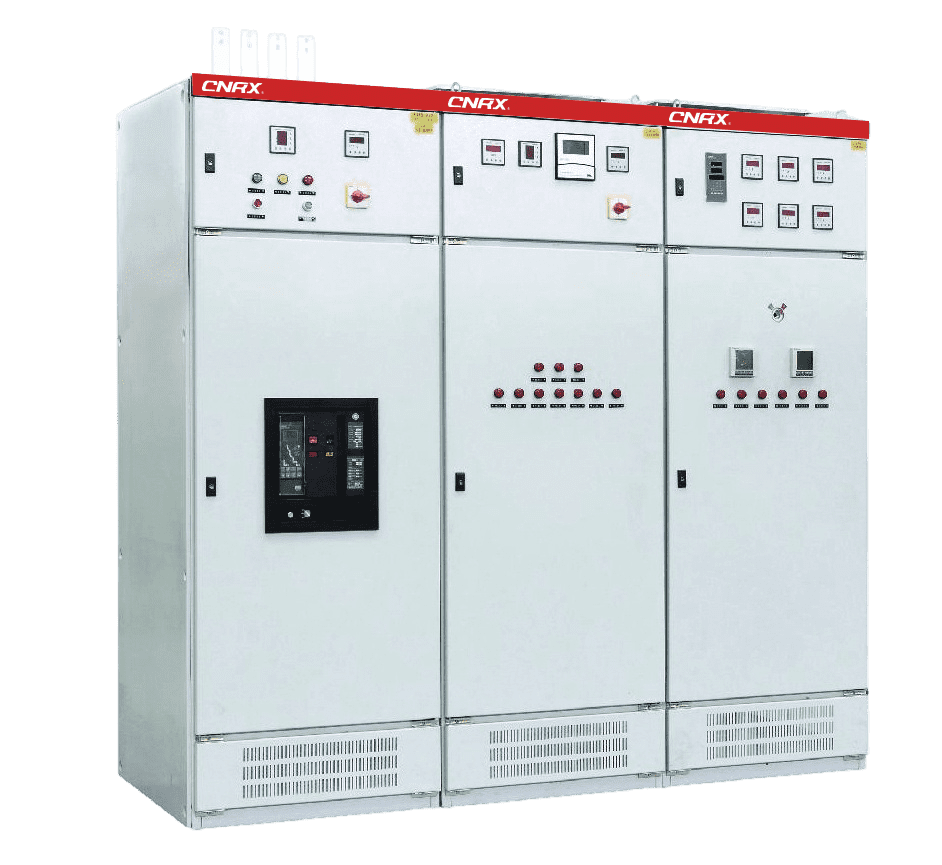

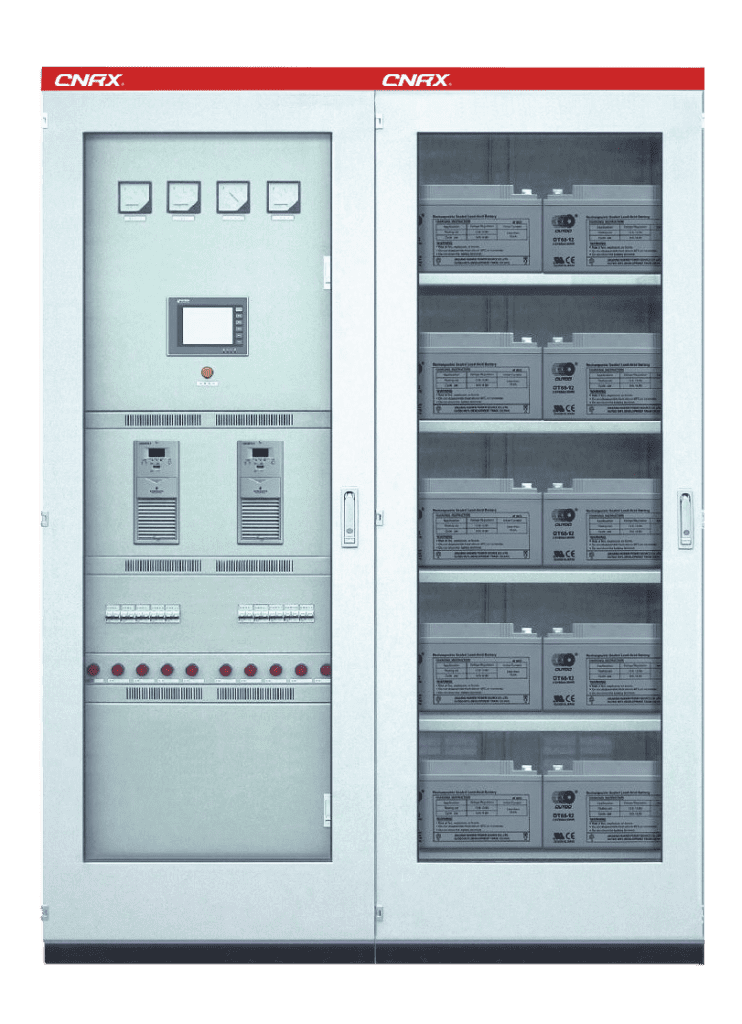

MDmax-ST low voltage switchgear is adopted with a modular structure in its structural design,

standard components and assemblies to achieve compactness and diverse fracture flexibility in the cabinet assembly scheme. It can be combined into different types of switches according to

requirements, such as fixed type, fixed partition type, drawer type. In terms of functionality, it

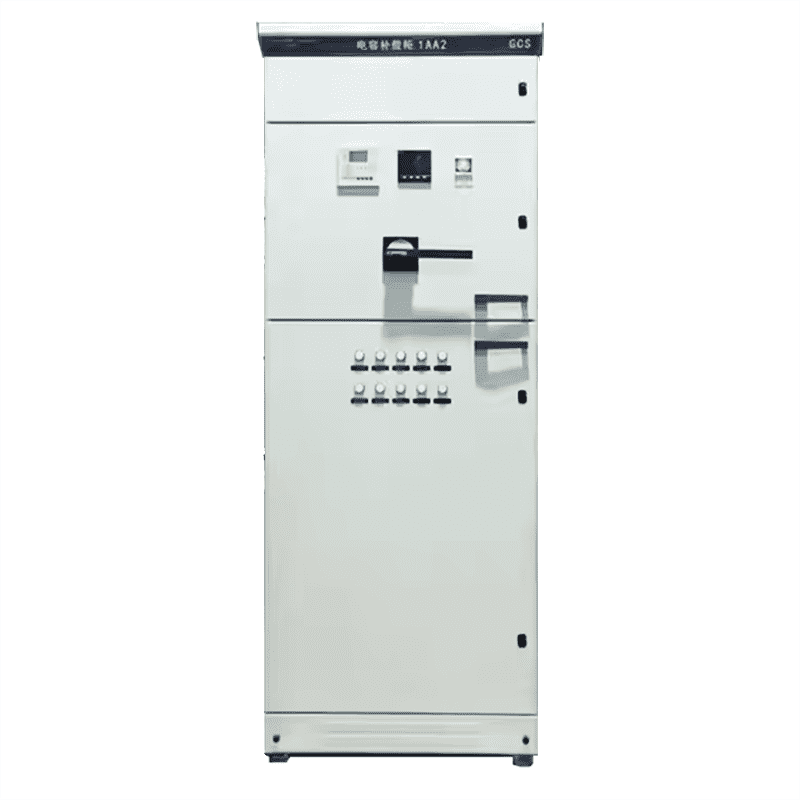

considers power distribution, reactive power compensation, motor control center (MCC),AC

frequency converter, soft start device, etc. MDmax-ST low voltage switchgear has the characteristics of multifunctionality and modularity, suitable for low-voltage distribution in various occasions, as well as motor control systems in enterprises such as metallurgy, chemical engineering, and power plants.

Product features

- The cabinet frame is adopted with the double folding technology of aluminum zinc steel plate, and modular holes are arranged on the frame at intervals of 25mm (K-profile), making the frame easy to assemble and sturdy. The entire frame is precisely connected by horizontal and vertical bolts, and the frame structure is maintenance free.

- The shell is covered with electroplating and powder coating to ensure the highest durability.

3、The top cover of the horizontal busbar area can be disassembled, making it convenient for on-site busbar installation. The main busbar system installed on the top of the switchgear is completely isolated from the functional units, cable area, and secondary line horizontal wiring area, ensuring sufficient safety distance between the busbar and operation and maintenance personnel.

4、Drawer style structure, capable of assembling up to 36 circuits, economical and reliable, saving on-site space. Three position conversion of drawer circuit can be achieved without reducing the protection level.

5、The drawer has movable components for positioning, and can be matched with three types of indicators: sound, light, and text. The drawer door panel and switch have a mechanical interlocking mechanism. When the switch is in the closed position, the drawer component door cannot be opened.

6、MDmax-ST can be optional front door of fully transparent explosion-proof glass. Easy observation and beautiful appearance.

Only logged in customers who have purchased this product may leave a review.

We are professional EV charger manufacturer.

This depends on the EV battery size, remaining battery capacity, and the type of EV charger used as well as environmental conditions such as temperature.Typically, an AC charger with an output power of 7–22 kW can fully charge an EV in between 3 and 6 hours.With a 50–200-kW DC fast charger, the charge time can be reduced to 10–60 minutes.

An AC charger provides AC power, which is then converted to DC power by an onboard charger inside the EV (before it reaches the battery). AC chargers are normally used in slow-charging applications such as home charging. A DC charger converts AC power from the grid into DC power, which is more efficient and supplies the batteries directly. Thus, the charging time is markedly shorter. DC chargers have higher power requirements and therefore a higher installation complexity. As such, the installation cost can be higher than that for an AC charger. DC systems are generally used in commercial/public charging applications where shorter dwell tines are needed

This depends on your situation. Fast DC chargers are ideal for cases where you need to recharge your EV quickly, such as at an intercity highway charging station or rest stop. An AC charger is suitable for places where you stay longer, such as workplace, shopping malls, cinema and at home.

.png) PV-Storage-Charging

PV-Storage-Charging-1.png) High & Low Voltage Switchgear

High & Low Voltage Switchgear Company Profile

Company Profile News Information

News Information Service Support

Service Support Cloud Platform Customized Development

Cloud Platform Customized Development Leisheng Charging International Platform

Leisheng Charging International Platform Leisn Home Charging Platform

Leisn Home Charging Platform

Reviews

There are no reviews yet.